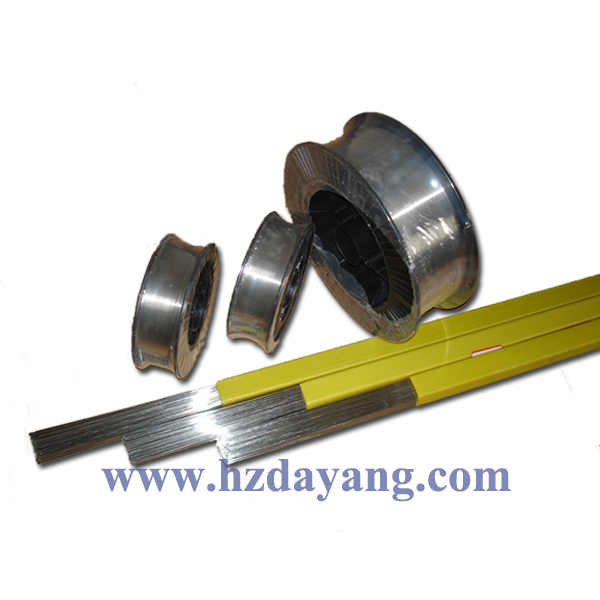

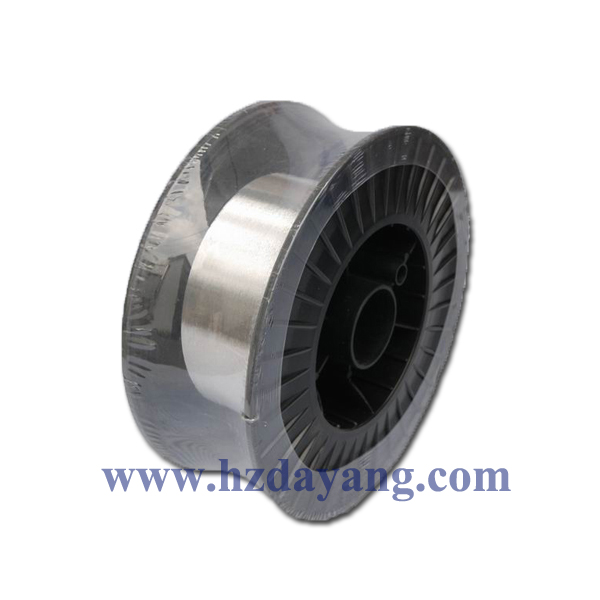

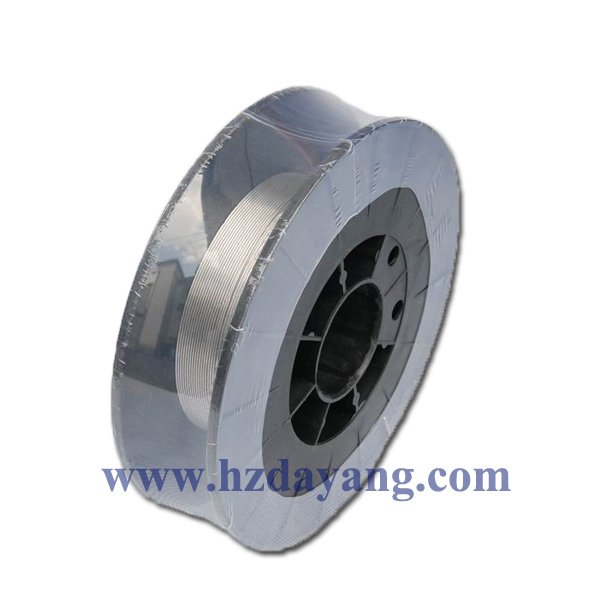

welding cable

We are the quality manufacturer of welding cable from China. We export welding cable, also provide OEM service of welding cable for you.

Our welding cable absolutely can fit your need with high quality and reasonable price. From raw materials to finished products, we strictly control every production step.

Any need of welding cable, please email us.

Retaled "Welding Cable" Keywords

Retaled blog

Outdoor electric soldering iron wire method---2013-09-03

To work outdoors frequently encountered problems .. welding power cord electric iron too much trouble , how not to tin wire electric iron alone can get the job done efficiently too high ! ! ! Actually very simple as long as a lighter can be complete the task ! look Carbon Steel Welding Electrode effect it ! effects still can ! ! then look at it before soldering required prior to welding power cord twisted work , it means the two wires twisted together , as to why you want to stay a Slingshot online tail it just for the next step is more easy to explain !

var addthis_config = {"data_track_addressbar":true};

correct selection of welding cables---2013-09-03

The overwhelming majority of users are using welding cable welding cable . Currently , the supply of welding cable Carbon Steel Welding Rodrandom not standardized , the common level of a welding current capacity of several files with the cable section is small, which not only affects the cable life ( cable temperature and current density, approximately proportional to the square cable protection insulated life with its temperature is increased by 10 ℃ decreased 1/ 2 ) , and consuming too much power.

var addthis_config = {"data_track_addressbar":true};

Safety requirements for welding cables---2013-09-03

welding cable should have good electrical conductivity and insulating outer layer , general welding copper ( multi-strand thin ) line, outsourcing insulating sleeve made of rubber , insulation resistance of not less than 1MΩ. 2 soft, lightweight , can be any bending and torsional easy to operate. 3 welding cables should have good mechanical damage ability , oil, heat and corrosion resistance properties. 4 welding cable length should be determined depending on the circumstances , the voltage increases too big , too short for working inconvenient, generally take 20-30 m cable length . 5 have appropriate cross-sectional area , welding cable cross-sectional area should be based on the size of Tungsten Welding Electrodes current , selected according to the provisions in order to ensure wires from overheating and burning insulation. 6 welding cable applications in the middle of the whole root there should be joint, take a long time for a short-term , the joint should not exceed two connectors made of copper , to be strong and reliable good insulation . 7 prohibit the use of metal construction factory operators , pipes or other metal wire used as a lap together . 8 welding cables shall not be placed on or near electric hot side of the weld metal to avoid burn insulation layer , while avoiding rolling wear. 9 welder welding cable and wiring must be copper or lead line the nose , in order to avoid secondary terminal board burn cause a fire. 10 welding cable insulation should be checked every six months . 11 welder and power strips connected to power lines, due to high voltage, in addition to ensure good insulation , but its length should not exceed 3m, if it proves necessary long lead time , safety measures should be taken to the interval , which should from the ground 2.5 m or more along the wall with porcelain cloth laying, laying along the power cord is strictly prohibited , not to fall into the mud .

var addthis_config = {"data_track_addressbar":true};

welding cable line to be adopted---2013-09-03

Welding cable : (YH cable ) stands for high-strength rubber welding cable , commonly known as the welding wire is YC Cable ( General rubber sheathed cable ) one. For wiring and connecting the secondary side welding electrode holder , Tungsten Welding Electrode dedicated cable , its characteristics are resistance, voltage is low. Operating voltage is typically 450V to 750V.Commonly used welding cable specification model has 16 square feet, 25 square feet, 35 square feet, 50 square feet, 70 square feet, 95 square feet, 120 square and so on.

var addthis_config = {"data_track_addressbar":true};

Check for detail

Check for detail