Contact Us

Contact:Shanzhong Yang

Tel: 0086-571-87169872 /87169873

Fax: 0086-571-87169573/63739139

E-mail: china@hzdayang.cn

Tel: 0086-571-87169872 /87169873

Fax: 0086-571-87169573/63739139

E-mail: china@hzdayang.cn

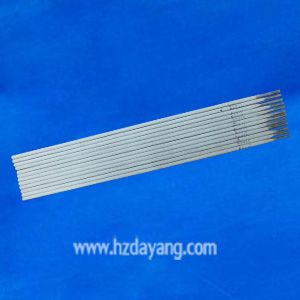

AWS E10015-G(2)

Suitable for welding important structures fabricated by alloy steel,e.g.high pressure vessels ,bridges as well as ocean projects etc.

Products Description

Comments

| Model Number | AWS E10015-G(2) |

| Brand Name | Ocean Welding |

| Size | 2.5mm 3.2mm 4.0mm |

| Applications | Suitable for welding important structures fabricated by alloy steel,e.g.high pressure vessels ,bridges as well as ocean projects etc. |

|

Chemical composition of deposited metal(%)

|

||||||||

|

C ≤0.2 |

Mn ≥1.0 |

Si ≤0.6 |

S ≤0.035 |

P ≤0.035 |

Cr 0.7-1.1 |

Ni - |

Mo 0.5-1.0 |

V 0.05-0.15 |