Contact Us

Contact:Shanzhong Yang

Tel: 0086-571-87169872 /87169873

Fax: 0086-571-87169573/63739139

E-mail: china@hzdayang.cn

Tel: 0086-571-87169872 /87169873

Fax: 0086-571-87169573/63739139

E-mail: china@hzdayang.cn

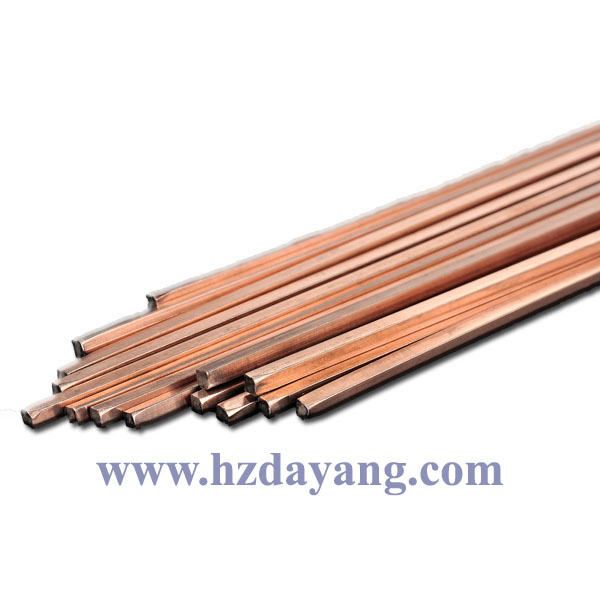

BAg10CuZn

The melting point is high, the sheet flood attachment plasticity is bad,is mainly suitable for the steel hard alloy copper, the copper alloy.

Products Description

Comments

| Brazing Alloy | Composition(%) | Melting Range(℃) | Applicable scope | ||||

| Ag | Cu | Zn | Sn | Min | Max | ||

|

HL301 (as:BAg10CuZn) |

10.0±1.0 | 53±1.0 | REM | 815 | 850 | The melting point is high, the sheet flood attachment plasticity is bad,is mainly suitable for the steel hard alloy copper, the copper alloy. | |