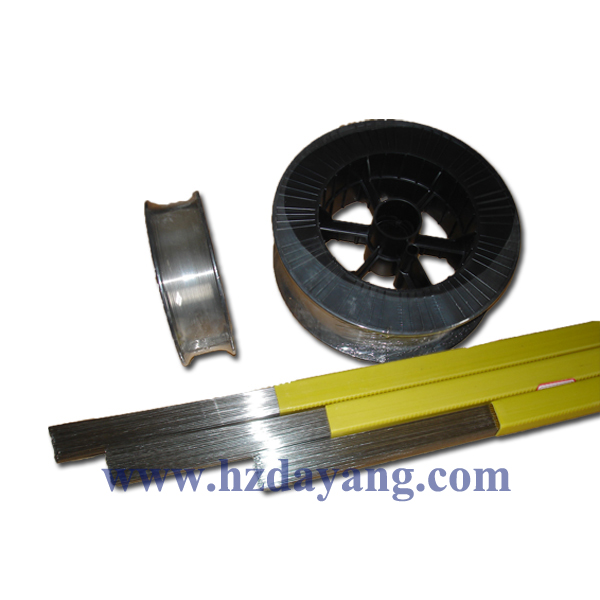

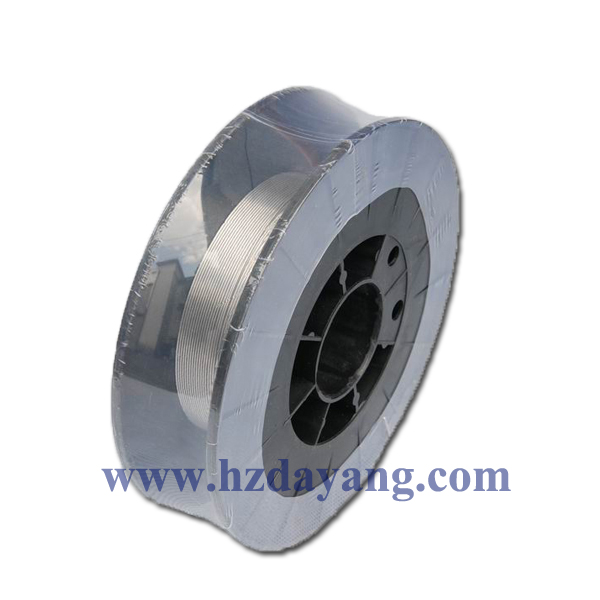

mig welding rod

We are manufacturer and supplier of mig welding rod. We have rich experience in manufacturing mig welding rod. From raw materials to finished products, we strictly control every production step.

We dedicate ourselves to manufacture and supply of mig welding rod with nice service.If you need mig welding rod, please email us.

Retaled "Mig Welding Rod" Keywords

Retaled blog

MIG welding materials and equipment---2013-08-30

MIG welding materials and equipment(1) Aluminum ① The mechanical properties of aluminum and chemical composition must comply with current national standards. ② used aluminum factory certificate must have books and materials, and meet the engineering requirements. ③ prepare the scene of aluminum custody and issuance of work.(2) ① The aluminum wire welding materials factory certificate must have booksCast Iron Welding Electrode and materials. ② The aluminum wire must be welded aluminum match. ③ argon gas purity of> 99.95%. ④ The welding wire, argon and other welding materials must be used according to regulations and keep it.(3) Equipment semiautomatic MIG welding machine (500A), wire feeder, welding torch, argon and argon gas cylinder flow meter. Angle grinder, stainless steel wire brush, hammer and wrench or other tools should be kept intact working conditions

var addthis_config = {"data_track_addressbar":true};

MIG welding safety measures---2013-08-30

MIG welding safety measuresSpot welding, construction staff should strictly implement the state in addition to the existing "construction and installation work barnyard safety technology" as well as on-site technical measures and regulation Stainless Steel Welding Electrodessafety, the special exaggerate the following points:(1) MIG welding radiation is strong, smoke more, the staff should pay more attention welding umbrella labor safety precautions.(2) Replace the contact tip to be closed when welding power source.(3) with better technology electrician maintenance staff.

var addthis_config = {"data_track_addressbar":true};

Specific measures MIG welding---2013-08-30

① prevent air pollution: pollution of major welding fume handling mainly the use of local ventilation, ventilation, supplemented by a comprehensive means to strengthen personal protection, thus improving the operating environment pollution. ② prevent light pollution: the scene illumination concentrated exposure, covering only live ranges. Set around the work area, isolating shed, the welding arc is generated Flux Cored Welding Wire in optical isolators in the construction area. ③ prevent the construction of noise pollution: the construction site to promote civilized construction, establish and improve the governance of man-made noise control system. Construction site noise machinery (such as air compressors, welding machines, arc planing, grinding machines, etc.) to set the closed shed isolation to reduce noise from spreading. ④ solid waste management: construction trash containers used lifting, non-random throw. The establishment of specialized construction site waste temporary storage sites. Regular production process waste collection towel collection, to approve the construction unit of the unit or premises for processing, consumer satisfaction.

var addthis_config = {"data_track_addressbar":true};

MIG welding construction environmental measures---2013-08-30

(A) in accordance with national and local (industry) regulations concerning environmental protection required by the company's environmental indicators and quality assurance manual, the establishment of environmental management system, develop environmental objectives, pollution prevention, waste reduction and energy conservation, to achieve harmony with the environment construction to achieve environmental governance standards(2) the main control measures meets every week, "construction site protection" regular work, sum up the previous construction site environmental governance, arranged Stainless Steel Welding Electrodes next stage of the construction site environmental governance. Each week the organization of a civil construction and environmental management by the responsible persons of the joint inspection, the inspection found the problem, depending on the circumstances, given time, will be one, measures to be addressed.(3) the construction of major sources of pollution and emissions of major pollutants ①, mainly for construction waste and dust generated during the welding process. ② optical radiation, mainly in the welding arc. ③ noise, the main sources of noise generated by the welding and mechanical equipment. ④ solid waste, primarily the remaining wire welding head, cutting and grinding bevel aluminum generated aluminum scrap powder.

var addthis_config = {"data_track_addressbar":true};

Check for detail

Check for detail