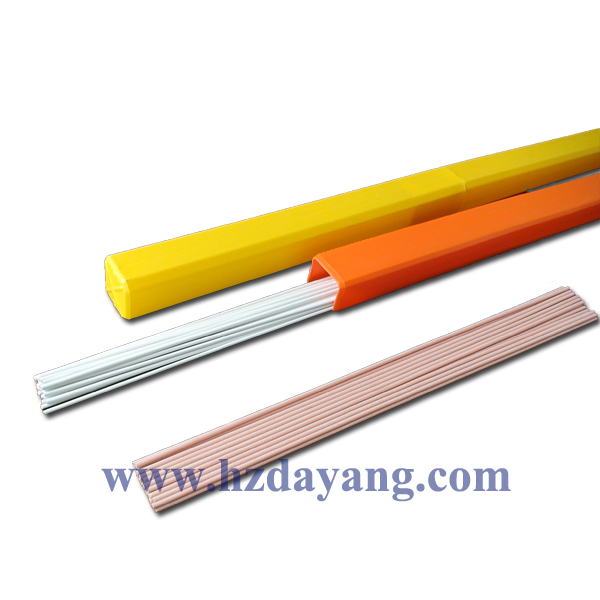

copper brazing alloys

We are the quality manufacturer of copper brazing alloys from China. We export copper brazing alloys, also provide OEM service of copper brazing alloys for you.

Our copper brazing alloys absolutely can fit your need with high quality and reasonable price. From raw materials to finished products, we strictly control every production step.

Any need of copper brazing alloys, please email us.

Retaled "Copper Brazing Alloys" Keywords

Retaled blog

brazing materials and brazing flux when brazing copper ---2013-09-02

You can use silver -based solder and copper phosphorus brazing . The melting point of silver -based solder moderate, technology is good, and has good mechanical properties and thermal conductivity properties , is the most widely used hard solder . For applications requiring high conductivity of the workpiece to be elected with high silver content solder B-Ag70CuZn . Vacuum brazing or protective atmosphere furnace brazing, to be used free of volatile elements of the B-Ag50Cu, B-Ag60CuSn such as solder . Lower silver content solder , cheap, high temperature brazing , brazing toughness is poor, mainly used Aluminium Welding Rods require lower copper and copper alloys . Silver copper phosphorus and copper-phosphorus brazing copper and copper alloys can be used for brazing , wherein the B-Cu93P has good fluidity, for electrical, instrumentation and manufacturing industries from shock loading of parts brazing, most suitable gap of 0.003 ~ 0.005mm. Copper-phosphorus silver brazing ( such as B-Cu70PAg) toughness and electrical conductivity than copper- phosphorus brazing good , mainly for high conductivity required electrical connections .

var addthis_config = {"data_track_addressbar":true};

brazing material---2013-09-02

Soldering flux brazing materials most widely used soft solder is tin- lead solder , and its wettability and spreadability with solder tin content increases. The brazing process and economy are good, joint strength is also well positioned to meet the requirements. w (Sn) 95% or more of the solder material is mainly used in the food industry and Stainless Steel Welding Rod, to reduce lead contamination. S-Sn60Pb and S-Sn63Pb lowest melting temperature , has superior process performance, primarily for the electronic device by hand soldering , wave soldering , brazing and melt dip brazing . S-Sn63PbAg reduce silver layer base material corrosion , to improve the solder creep and fatigue properties . S-Pb60Sn and S-Pb60SnSb solder is the most common , widely used in radiators , pipes, electrical connectors , household products, and engine Aluminum Electrode. Cadmium -based solder is best soft solder solder heat resistance , joints withstand temperatures up to 250 ℃, and has good corrosion resistance. Using cadmium -based brazing copper and copper alloys , the interface is easy to form brittle copper cadmium compounds , it is necessary that such rapid heating resistance brazing method

var addthis_config = {"data_track_addressbar":true};

brazing---2013-09-02

Brazing copper and its alloys to be used before mechanical cleaning or sanding way to clear the surface of the oxide , a chemical clean way to remove grease and other contaminants . Copper and its alloys can be used iron , crest , flame, induction , resistance, and other methods of heating furnace brazing. In the oxygen-containing copper furnace brazing can not use hydrogen atmosphere , it should avoid the use of flame brazing large assemblies to avoid hydrogen embrittlement . Brass furnace brazing , to avoid the evaporation of zinc , preferably the surface of the brass plating first , and then brazing. Prolonged heating of the copper alloy lead is likely to precipitate lead , there may be defects in the connector . Aluminum bronze brazing of aluminum in order to prevent the diffusion of the silver solder , Stainless Steel Welding Rodheating time as short as possible , the surface of copper or aluminum bronze , nickel, etc. I belong . Bronze soldering , the best Copper Brazing Alloys temperature below 300 ℃ solder to avoid aging softened. Bronze brazing , the solidus temperature should be selected higher than the quenching temperature (780 ~ C) solder , brazing aging treatment after quenching . For prone to cracking from silicon bronze , phosphor bronze and copper -nickel alloys, be sure to avoid thermal stress cattle production , rapid heating methods should not be used

var addthis_config = {"data_track_addressbar":true};

Brazeability---2013-09-02

Copper and copper alloys are usually divided into copper ( copper ) , brass , bronze and copper-nickel alloy four categories, they brazing surface oxide film mainly depends on the stability and brazing process on the material properties. The surface may be formed of copper oxide, copper oxide, cuprous oxide is easily reduced both gas reduction, it is easy to remove the flux , the brazing of copper is very good. To prevent the occurrence of hydrogen embrittlement , can not be a hydrogen containing reducing atmosphere brazing. Containing only zinc brass , surface can be zinc oxide or cuprous oxide of oxides , zinc oxide, although relatively stable, but difficult to remove . Manganese oxide, manganese brass surface is relatively stable , difficult to remove , should be the active agent in order to ensure a Brazing Alloys solder wettability . Bronze, cadmium bronze surface oxide film are easily removed , silicon bronze , beryllium oxide film , while relatively stable, but difficult to remove . And w (A1) more than 10% of aluminum bronze, mainly aluminum oxide surface , it is difficult to remove , to adopt a special flux . Copper-nickel alloy on the surface of nickel oxide and copper oxide easily removed , but should be used containing no phosphorus brazing solder , since the joint in order to avoid cracking .

var addthis_config = {"data_track_addressbar":true};

Check for detail

Check for detail